The uniformly dispersed carbon nanotube slurry is coated on the substrate, the carbon nanotube is bonded to form a planar conductive film structure, and the carbon nanotube surface heat source is formed by covering both sides of the conductive film with metal electrodes;After power up , the carbon atoms of carbon nanotubes vibrate under the action of electric field, and the electrons around the nucleus undergo energy level transition. When they migrate back to the ground state, they release energy in the form of infrared ray, and then form a surface heating body with uniform heating.

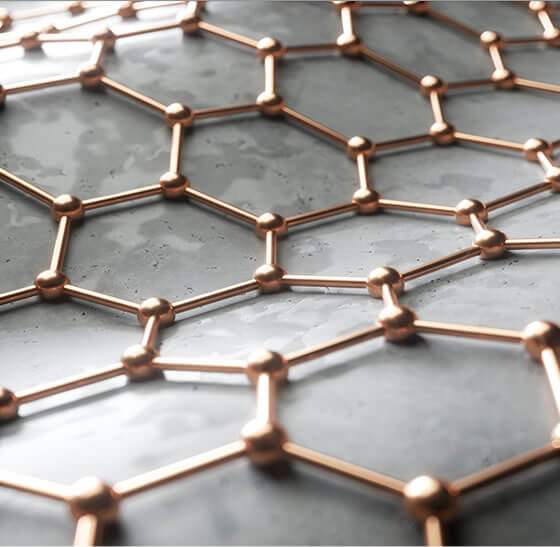

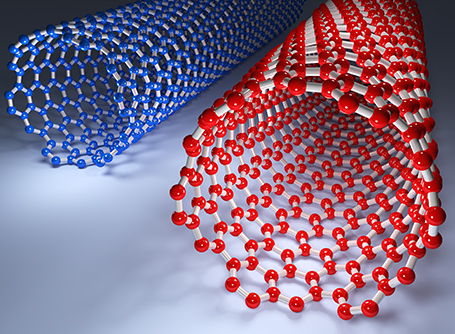

Carbon nanotubes (CNTs) are seamless tubular structures coiled from graphene sheets, with diameters ranging from several nanometers to tens of nanometers and lengths of micrometers or even millimeters. As a one-dimensional nano material, it has light weight, perfect connection of hexagonal structure, and excellent physical properties such as high electrical conductivity, high thermal conductivity and high stability.

Electron mobility of carbon nanotubes up to1×105 cm2/(V s)

Thermal conductivity up to 6600W/(m•K)

It has acid and alkaline resistance and can improve the oxidation resistance of the composite

The conversion efficiency of electric-thermal radiation is as high as 83%

The electric heating conversion efficiency is up to 99.8%

High temperature resistance (≥130℃), high temperature stripping resistance (>8h)

Acid and alkali resistance (pH≤1,≥13), flexural resistance (100,000 times)

5s rapid heating

1 minute to reach the target temperature more than 90%

Workday 9:00-18:00